I recently had one of my Youtube viewers ask for help with the thread tension on her Janome Horizon Memory Craft 8900 QCP, one of the sewing machines I also own.

She was trying to sew a straight seam and her machine was skipping stitches. In case you may also have this problem with your machine, here are some suggestions (the instruction manual pages refer to this specific model of Janome sewing machine):

First, get out your sewing machine's instruction manual - you're going to need it!

You should always have your sewing machine's manual close at hand.

Let’s start at the beginning - winding the bobbin. The bobbin needs to be tightly wound as a loosely wound bobbin can cause problems. When winding the bobbin, ensure that you are running the machine at top speed - move the speed control slider over to the far right (see p. 8 in your manual). This will help to wind the bobbin tightly. Be sure that you are following the correct thread path when winding the bobbin (see p. 19 in your manual). You want to ensure that the thread stays in this thread path as you are winding the bobbin as sometimes it can slip out and this will result in uneven bobbin winding. If you’ve done this and are confident that the bobbin is wound tightly, …

Pretty blue Janome bobbins

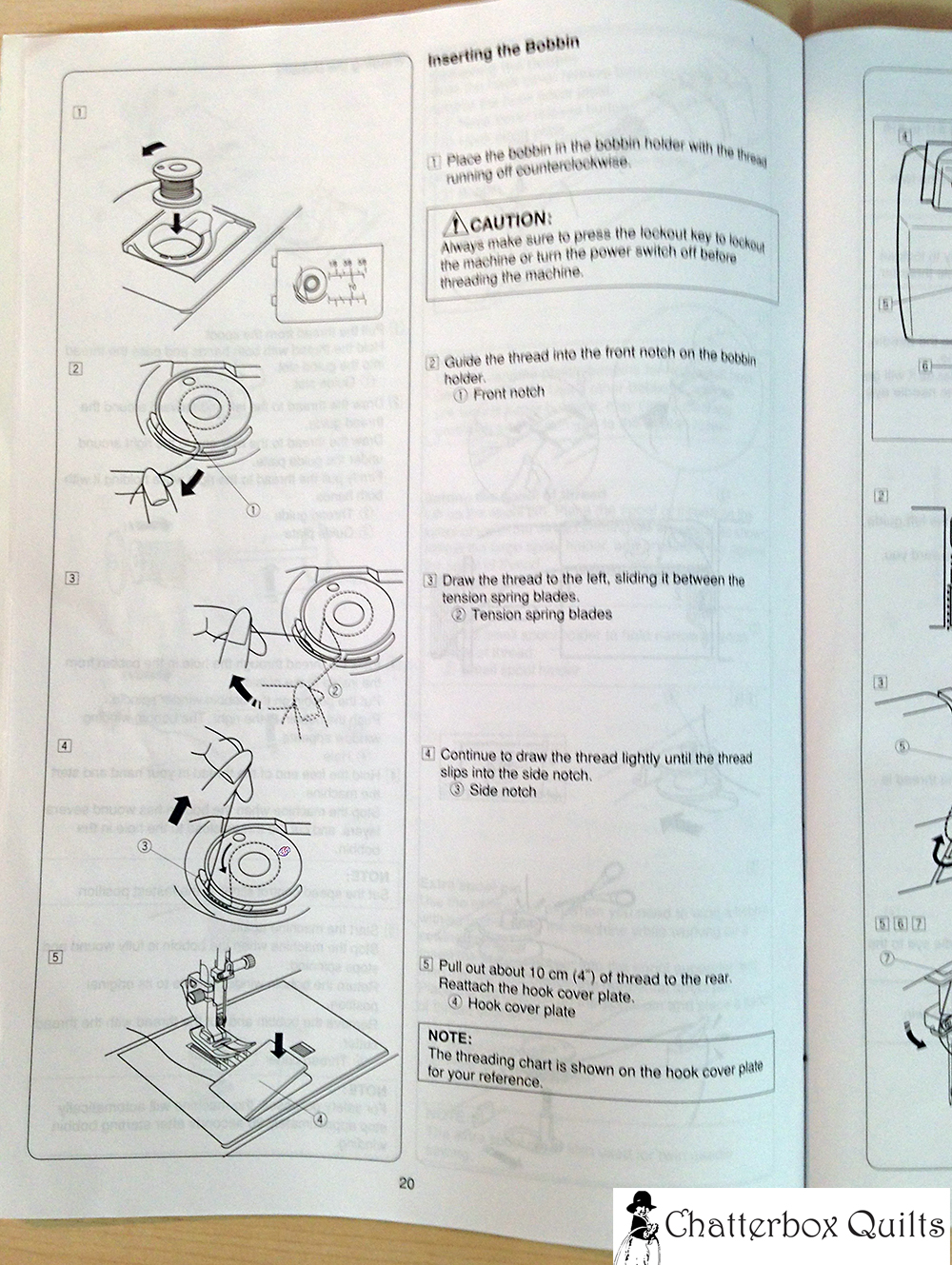

Check to ensure that you have put the bobbin in the machine correctly. For this model of the Janome, the bobbin should be inserted counterclockwise (see p. 20 in your manual).

Check your manual for the correct way to insert the bobbin.

I have several machines and always have to check this out as the bobbins in some machines go in one way and some the other, so just be sure that the bobbin is in the correct way for your specific sewing machine. For my model of Janome the thread fits into the front notch in the bobbin holder and goes to the left into the side notch. Again, if the thread isn’t catching in all these areas, this will cause tension problems.

Ensure that the bobbin is inserted correctly - the thread runs off counterclockwise for my Janome

I’m not sure if you’re using the same thread in the top of the machine as in the bobbin. If you are, the thread tension dial should be set to “Auto”. If you are using two different weights/types of thread, you may have to change the tension to either higher or lower (see page 12 in your manual).

Check and adjust your thread tension, if needed.

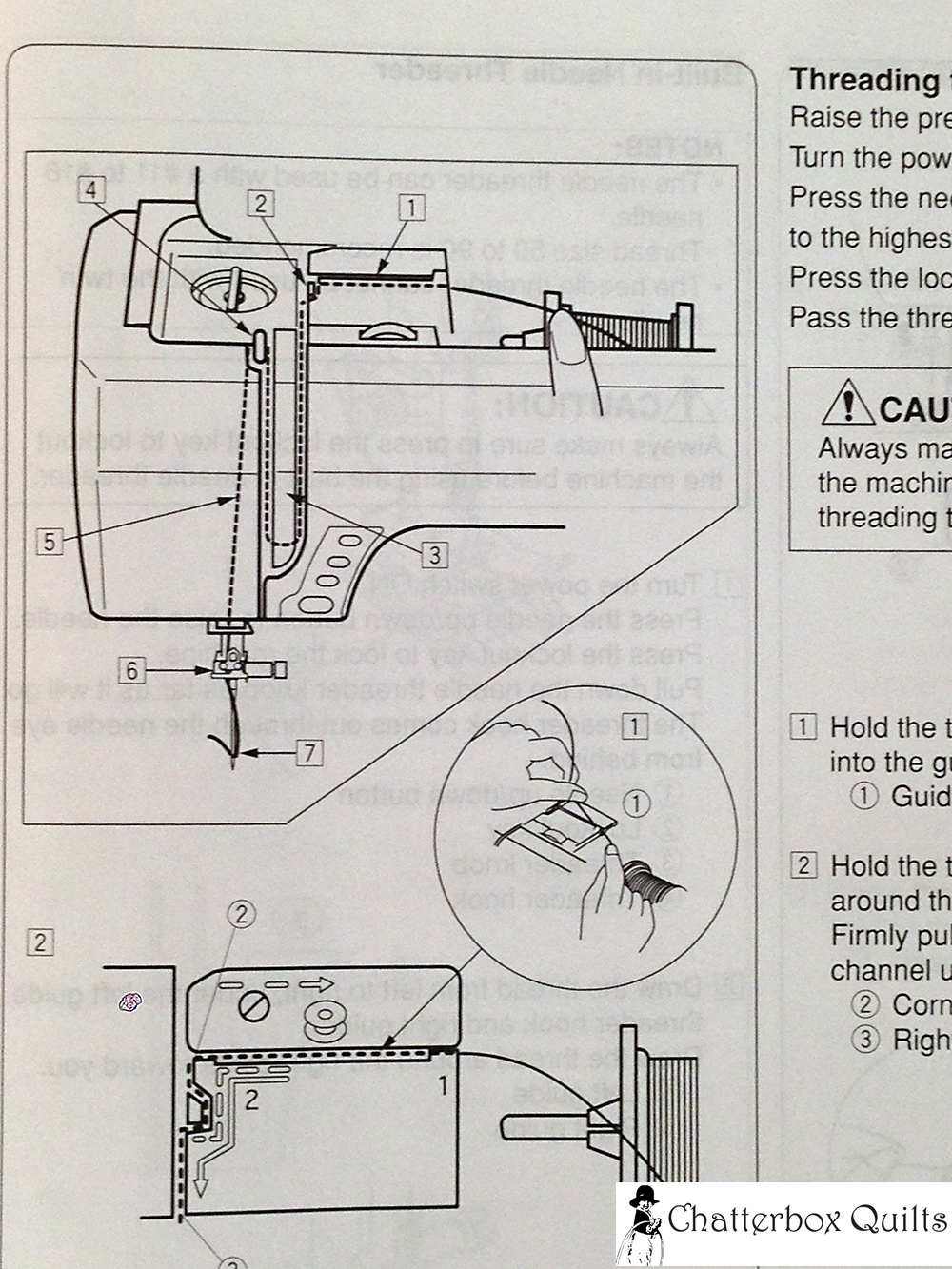

Next I would check to ensure that your top thread is correctly threaded. Again, it’s easy to miss one of these areas or the thread can sometimes pop out and this causes problems.

Do you know your sewing machine's thread path? If not, check your instruction manual.

Check page 21 in your manual to ensure that the top thread is correctly threaded. Remember to raise the presser foot when threading the machine and have the needle at the highest position. Threading the machine with the presser foot down can result in improper thread tension.

Check your instruction manual for the proper way to thread your sewing machine.

Changing the needle can sometimes help as well. Again, ensure that you are using the correct needle size for the thread you are using. I usually use an 80/12 or 90/14 in the machine and haven’t had any problems. You can check for the appropriate needle size on page 17 of your manual.

You can also try cleaning out the bobbin area to ensure that there isn’t any lint or stray threads that are causing the problem. See page 101 in your manual to see how to take out the bobbin case and clean the area. Take a good look at how the bobbin case is installed before removing it as it has to go back in a certain way to work properly. There is also a screw on the bobbin case that you’ll see when you take it out. If the thread is running out of the bobbin case too quickly, you may need to tighten the screw. If you can’t get it to come out at all, you may have to loosen it a bit. Check out this blogpost to see what I mean.

Take out the bobbin and clean the bobbin area after each project.

I hope that some of these steps help you with the thread tension. If you are still not able to get the tension the way you want it, I would suggest calling up your local Janome dealer and they should be happy to help you out.

Download the free Get Out of the Ditch! guide to learn how to start free motion quilting by clicking here.